At Sunsho Pharmaceutical, we provide a full range of services on everything from selection of raw materials and formulation to development, design, manufacturing and packaging. All of these procedures are enacted to offer our customers with high quality products at competitive prices in a short delivery time.

Whether you are considering entering the health food industry or developing new products such as pharmaceuticals, foods, or cosmetics, we are ready to help you.

Please feel free to contact us.

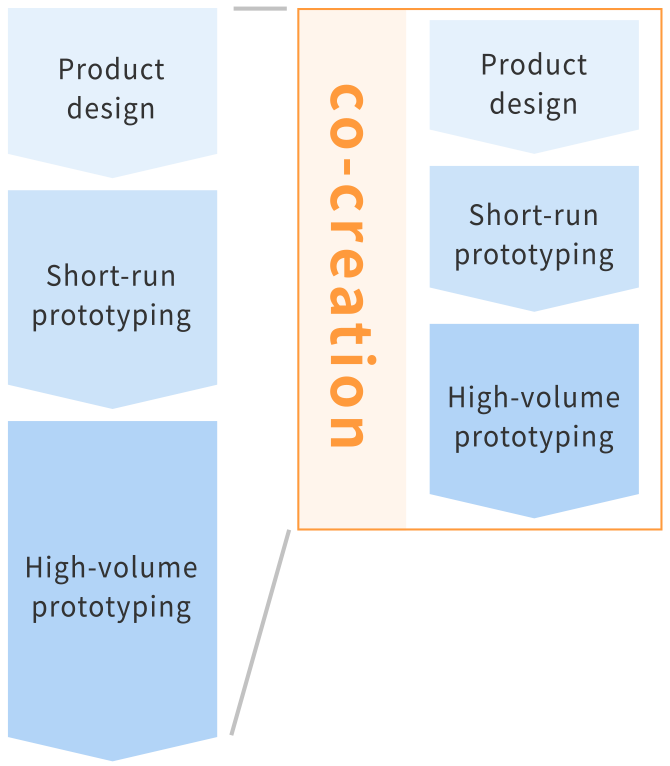

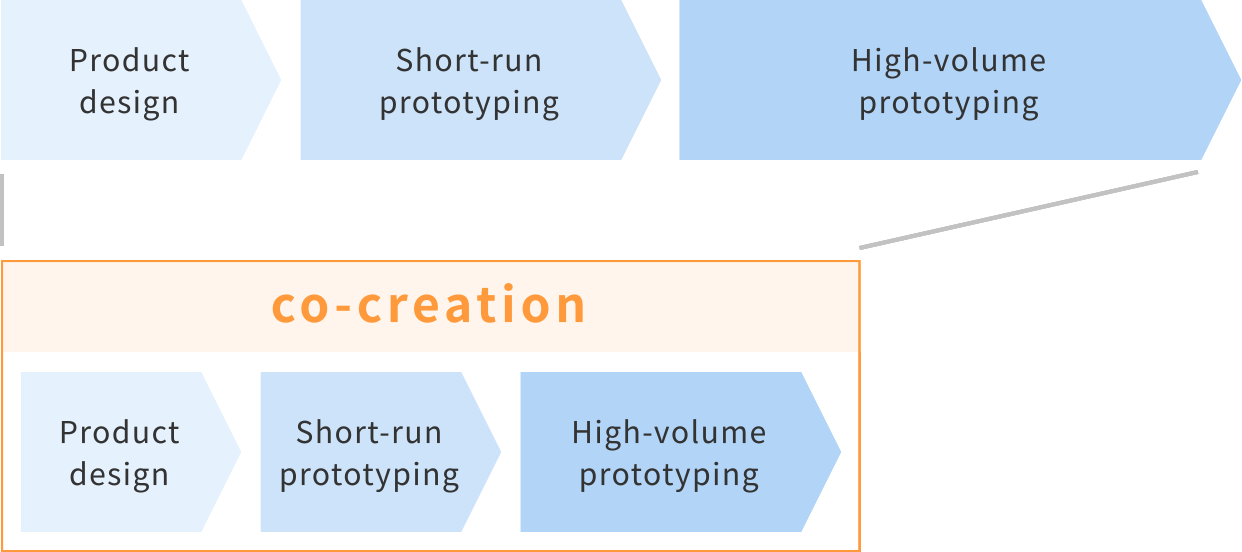

The "Application Development Center (ADC)," is a new prototype experience studio that opened in 2020. Here we work with customers in full transparency during the prototyping process, reducing the time required for repeated prototyping, delivery, confirmation, and review due to an imprecise sense of direction. The prototyping time, which is normally around three months, is cut down to around two months. In addition, by optimizing each process from order registration to shipment, the development and manufacturing lead time has been reduced to about half the normal time.

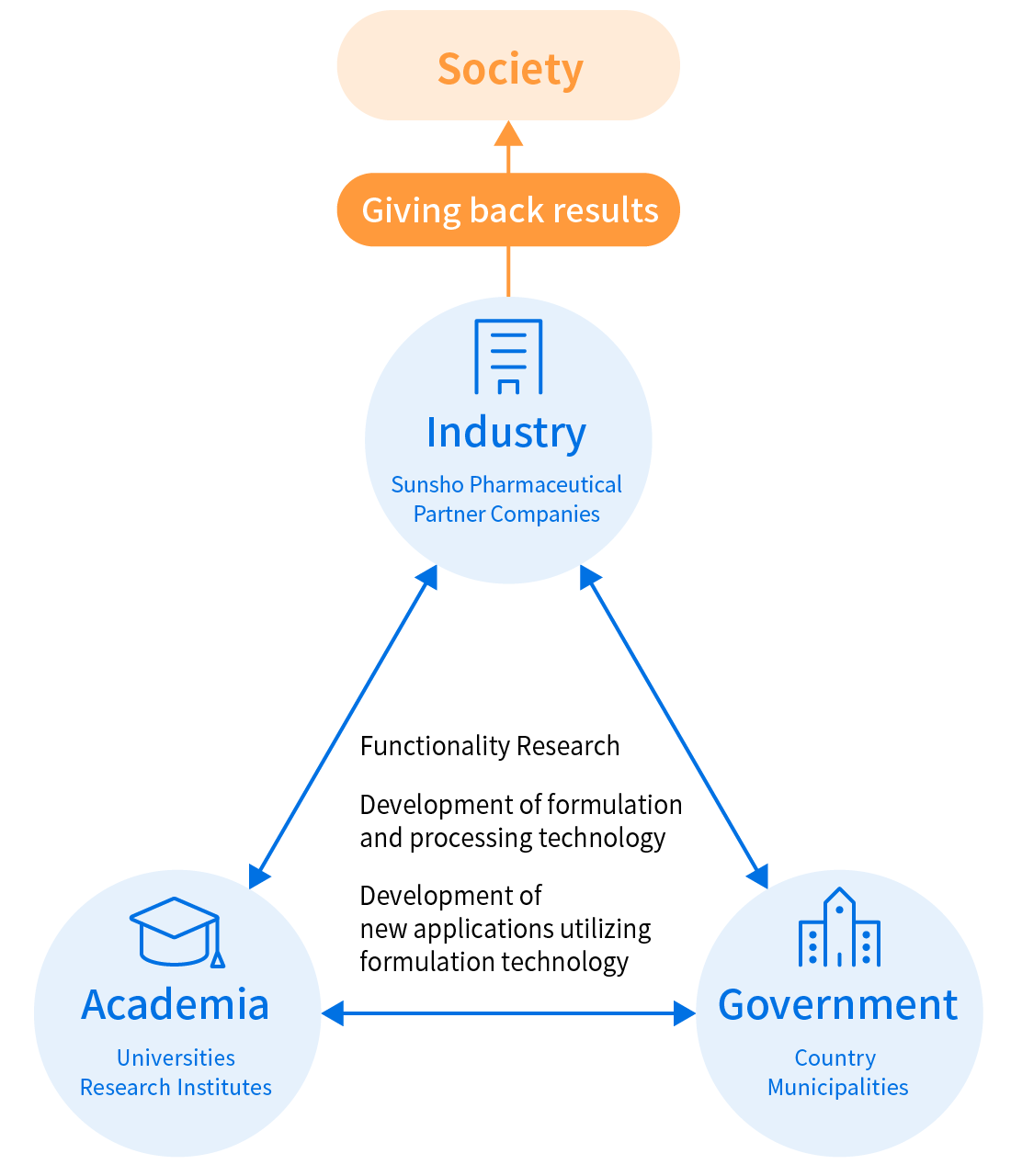

We started operation the Innovation Center in November 2022. We have taken on the challenge of producing original and new formulations as well as using cutting-edge technologies of easy swallow capsules. We fulfill customers’ request.

●Accurate and efficient product development

●Appropriate delivery of information to assist decision-making

●Collaborate with business, government, and academia to address societal and economic issues and to create new value.

Sunsho Pharmaceutical adapts a flexible approach to its operations. Personnel, operating systems for the production line, and production line operation systems are adjusted as needed to meet the urgent needs of our customers. Additionally, since we maintain a surplus of raw materials in our inventory, we can always assist with substitutions or distributed purchasing as required.

We have nine production facilities, including our Nanryo Plant, one of the largest soft capsule plants in Japan. With this production capacity, we can support the stable supply of our customers' products.

| Name of factory | Product | Daily production | Monthly production |

|---|---|---|---|

| Nanryo Factory | Soft capsules | 10,000,000 capsules | 300,000,000 capsules |

| Kuzawa Factory | Seamless capsules | 661 ㎏ | 19,833 ㎏ |

| Oobuchi Factory | Tablets Granules Hard capsules | 4,222,200 tablets 1,322 kg 4,255,500 capsules | 12,666,660 tablets 39,666 kg 12,766,660 tablets |

| Atsuhara Factory | Seamless capsules Jellies/mini-drink products | 2,044 kg 13,333 products | 61,333 ㎏ 400,000 products |

| Product | Daily production | Monthly production |

|---|---|---|

| Aluminum packaging | 174,000 packages | 5,220, 000 packages |

| PTP packaging | 543,000 sheets | 16,290,000 sheets |

| Three-side seal packaging | 316,077 packages | 9,482,333 packages |

| Stick packaging | 3,000,000 packages | 9,000,000 packages |

| Bottled packaging | 30,875 bottles | 926,250 bottles |

| Secondary packaging | 61,833 packages | 1,855,000 packages |