Simple manufacturing methods and shapes

for versatile applications to a variety of products

Compression-molded powders and granules are a dosage form that can be mass-produced due

to its relatively simple manufacturing process.

Produced as a pharmaceutical product, it accounts for more than 30% of all dosage

forms and is also widely used in health foods, confectioneries, detergents, chemical catalysts, and industrial catalysts.

We offer various coating technologies to meet a wide range of requirements.

Features and benefits

-

Easy to ingest

Compared to other dosage forms, tablets are compressed at a higher pressure, resulting in a smaller size, higher specific gravity and a smoother surface. All these attributes make this form easier to swallow. -

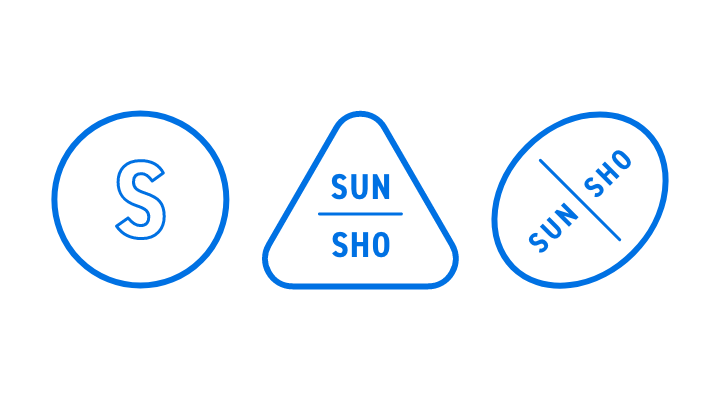

Diverse shapes

In addition to round shapes, a variety of other shapes, such as triangular and football-shaped, can be produced. Laser printing of letters and patterns is also available. -

Various functionalities

It is possible to add functions such as enteric solubility and sustained release to control the release site and time of the drug. They may also be produced in formats such as chewable and lozenges for users to enjoy the flavor. -

Coating with film or sugar

Tablets can be coated to provide benefits such as masking the taste, adding color, masking odor, prevent powder loss, maintain an attractive appearance and to protect ingredients that are unstable to light and moisture.

Tablet types

-

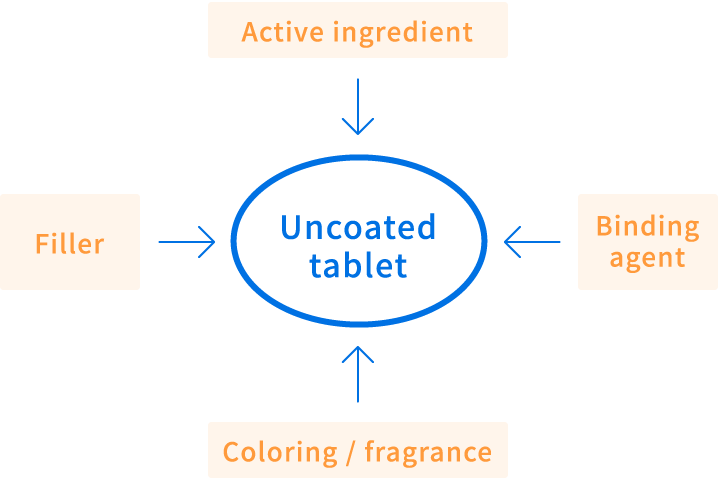

Uncoated tablets

This is a basic form of tablets with active ingredients pressed into shape along with fillers, binding agents, agent for strengthening, coloring and fragrances as required. It can be produced in different sizes and shapes by using various molds. -

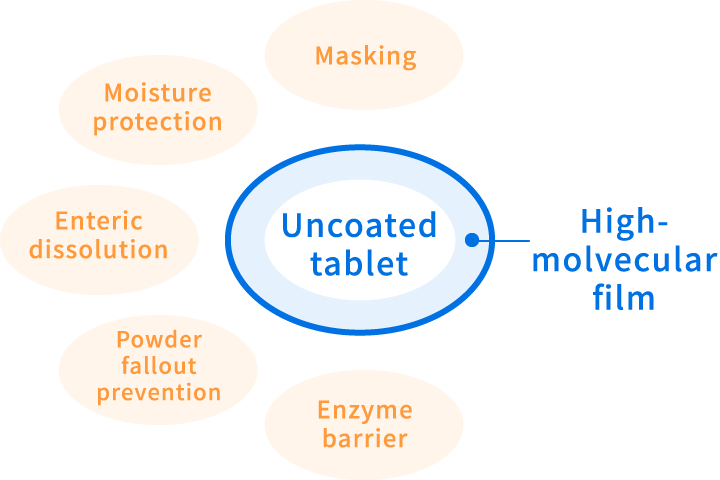

Film-coated tablets

Tablets can be coated with high-molecular film to mask unpleasant tastes and smells, provide protection from light and moisture or add specific dissolving characteristics such as enteric dissolution. The film can be made of natural resins, corn protein, cellulose HPC or HPMC, or dietary fiber, depending on the intended use. -

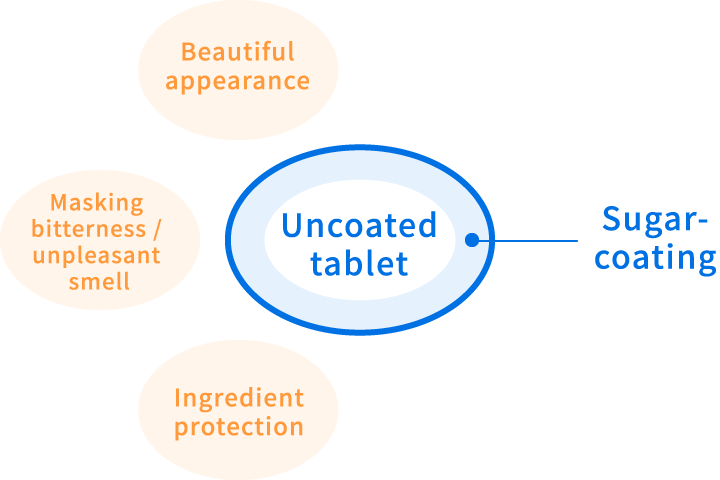

Sugar-coated tablets

Tablets can be given a sugar coating to mask the taste and odor of the ingredients, protect ingredients that are unstable to light and moisture and enhance the appearance of the tablets.

Non-sugar coating may be used to reduce calories, or sugar-coating may be made thinner to keep tablets compact. -

Chewable / orally dissolving tablets

Chewable tablets are ingested by chewing or licking them in the mouth and therefore do not require water.

Orally disintegrating tablets are designed to quickly dissolve in the mouth. Similar to chewable tablets, these tablets are suitable for those who have difficulty swallowing or for ingredients that should act or be absorbed in the mouth.