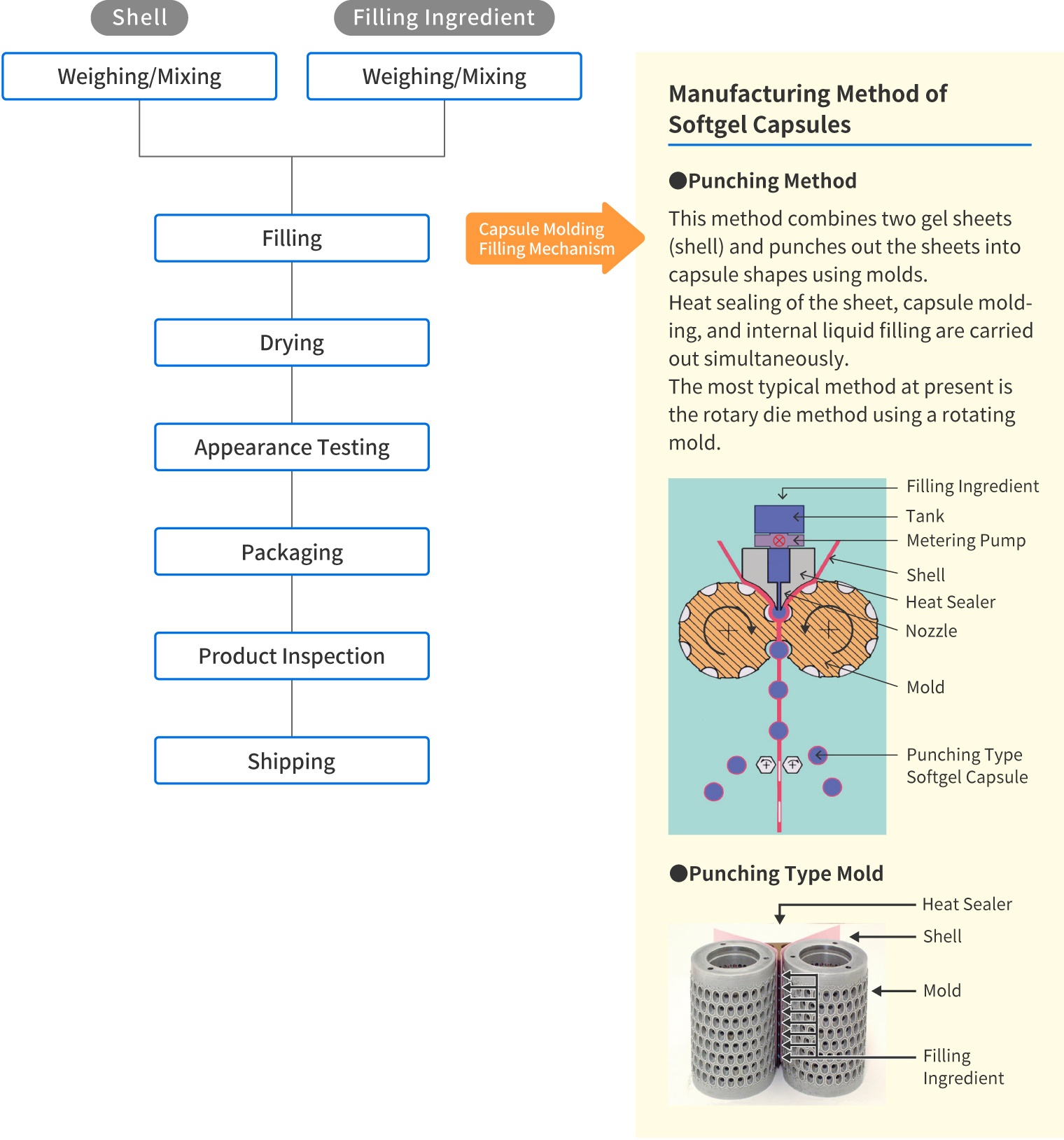

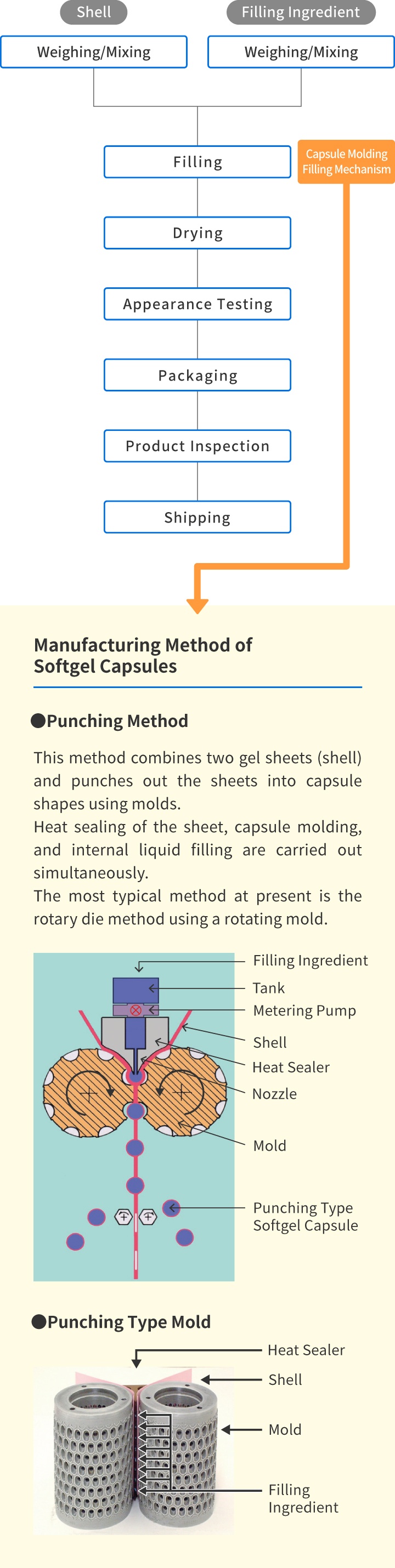

Flexible Design and High Barrier Properties Firmly Protect Fill Ingredients

Airtight and Stable Softgel Capsules Support Ingredient Delivery

Oil-based liquids and powders containing liquids can be encapsulated in an airtight dosage.

Used in various products such as supplements, pharmaceuticals, cosmetics, and sundries.

Solutions Provided by Sunsho Pharmaceutical Softgel Capsules

- ・Enhances absorption (bioavailability) of insoluble drugs.

- ・Achieves formulation uniformity even for active ingredients of 1 mg or less.

- ・Accelerates product development with a simpler manufacturing process and easier validation.

- ・End-to-end support from clinical trial drug manufacturing to commercial production.

Characteristics, Advantages

-

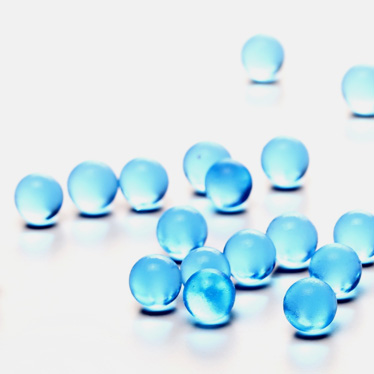

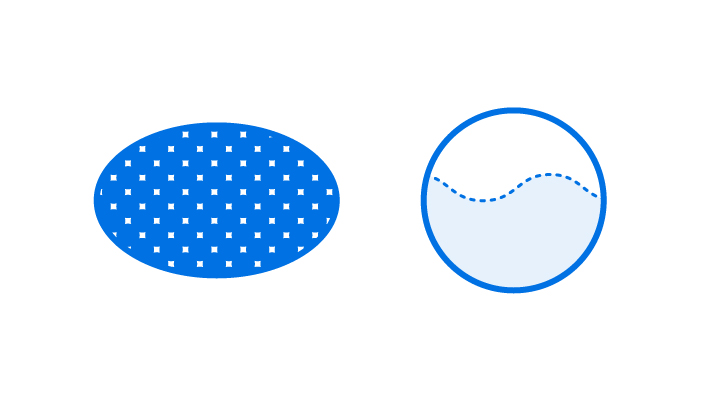

Highly Airtight and Stable

Highly airtight and protects the fill ingredients from oxygen, resulting in superior stability compared to tablets and hard capsules. -

Formulation of Active Ingredients

Suitable for active pharmaceutical ingredients such as oil-based powders and hydrophobic liquids, which are difficult to process into solidified formulations such as tablets, granules, and hard capsules.

Also suitable for formulation of self-emulsified active pharmaceutical ingredients. -

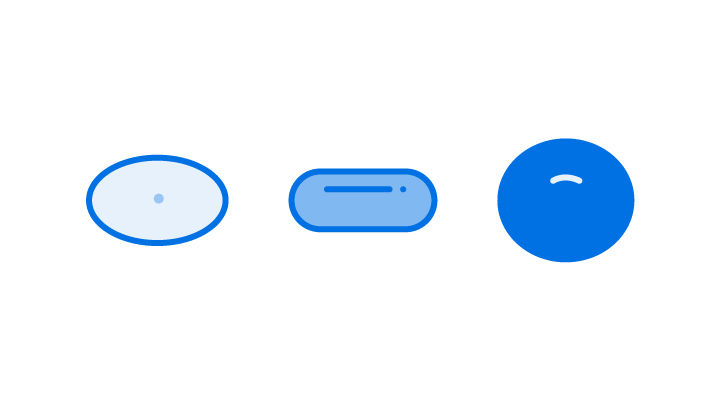

Highly Flexible Product Design

Flexibility in choosing the color and appearance (size and shape) of the shell to ensure distinctiveness.

Furthermore, characters and objects can be printed on the shell with a laser marker allowing display of product codes directly on the capsule or tablet.

Softgel Capsule Shapes

-

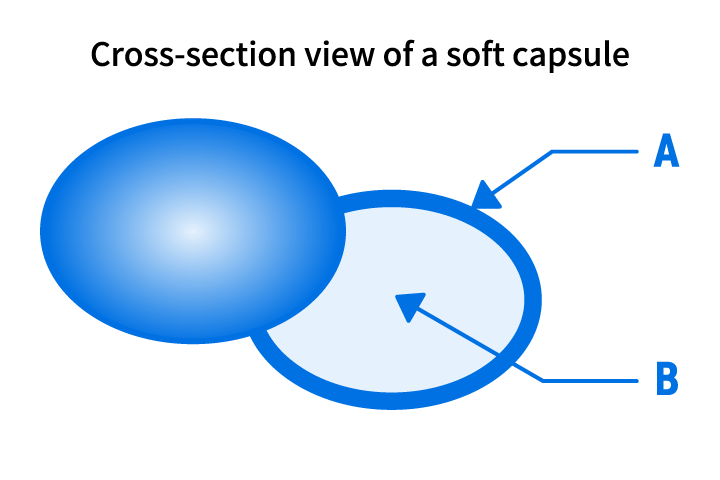

A. Shell

- ・Film made of gelatin, glycerin, etc. with a thickness of 0.2 to 0.8mm

- ・Coloring agents can be blended and possible to coat

B. Filling Ingredient

- ・Oily liquids such as vitamin E and carotene

- ・Oil-based compounds